The industry is maturing in its ability to measure static pressure, so it’s time to dig into the finer disciplines of measuring and interpreting HVAC system static pressure.

With growing information available on basic static pressure testing, it’s time for an article taking a deeper look into a few advanced pressure measurement principles for residential and commercial HVAC systems. The industry is maturing in its ability to measure static pressure. Since so many technicians have advanced beyond basic testing, it’s time to dig into the finer disciplines of measuring and interpreting HVAC system static pressure.

Awareness of these advanced tests will significantly improve your testing skills in the field, but may not apply to every system.

Beyond Basic Testing

Consider a trip to the doctor. Nearly every visit includes a blood pressure test, but certain circumstances require an electrocardiogram (EKG). Likewise, when basic static pressure testing raises questions and doubt, it’s time for advanced tests to provide more accurate diagnostics.

First step: Identify the equipment manufacturer, model number, fan motor horsepower, and optional internal components such as non-factory filters, additional heat exchangers, or any accessories included in the airside of the system.

This information is gathered by reading nameplate data, inspecting the system, and recording the information. Many of these variables can affect your static pressure readings and have a significant impact on diagnostics.

Refer to Manufacturer’s Specifications

All equipment manufacturers publish installation instructions and fan tables that include footnotes for measuring and interpreting static pressure readings. Nearly all specifications are searchable and downloadable on your phone or tablet. Be certain the specifications match the equipment, or your diagnostics could miss the mark.

Plot Fan Airflow

For example, static pressure measurements combined with fan RPM are used to plot fan airflow on fan curves or fan tables published for each piece of equipment. These tables and curves often include information about how to measure with a variety of equipment options and conditions.

Fig.1: Residential furnace showing where you take pressure measurements and what to do with the results when calculating Total External System Pressure. Photo courtesy NCI.

Inspect the Fan and Drives

When testing pressures in the field, remember that manufacturer’s specifications were taken on brand-new equipment under laboratory conditions. Equipment that is older, dirty, damaged during shipping, or poorly maintained will not match published specifications because- it is not performing under similar rated conditions.

Inspecting the system may turn up a dirty fan, slipping belt, installation instructions stuck in the cooling coil, equipment insulation in the filter, or a fan rotating backward.

Coil and Heat Exchanger Pressure Drops

Consider how a coil was rated. Is the published coil pressure drop rating taken when the coil is wet, or when it is dry? As airflow changes through a coil, the pressure drop increases or decreases at more than twice the rate of the change in airflow.

Equipment designed for colder climates may offer a high heat model with a larger heat exchanger. Is this a high-heat or standard heat unit? A high-heat heat exchanger will have a higher pressure drop that will be invisible to a total external static pressure measurement but must be accounted for in your interpretation and diagnosis.

Coil and heat exchanger pressure drops are internal to the equipment and included in the rated system pressures by the manufacturer. It’s up to you to decipher the specifications so you can accurately interpret your readings.

Electric Heat Strips

When electric heat strips are installed, these will not show up as an external pressure drop because they are normally installed within the equipment. A further search of heat strip specifications reveals a published pressure drop at specific airflows.

Fig. 2: Measurement locations on a typical commercial HVAC system. Photo courtesy NCI.

This pressure drop is added to the measured total external static pressure (TESP) measurement to accurately interpret pressure readings. If the heat strips are dirty, just turn them on for a few minutes to activate the “self-cleaning mode”. Then use the published pressure drop as your measured pressure.

Do not drill test ports for pressure measurement near heat strips — the risk of electric shock is way too high.

Economizers

In package equipment that includes an economizer as an accessory, measure equipment entering pressure downstream of the return duct dampers and economizer louvers. Some manufacturers publish data for this accessory, others do not.

For systems without an economizer, equipment entering static pressure is measured where the return duct enters the equipment. Since an economizer requires the installation of a return air damper at that location, followed by the economizer louvers, the test site for equipment entering pressure will change depending on manufacturer specifications.

Air Filter Pressure Drop

Some specifications include the filter as an internal pressure drop that is included in the total external static pressure specification. Other specifications exclude the filter from the rated total external static pressure. It’s your job to study the specification and interpret your readings correctly.

Filters can also be changed at any time. Do the current filters match the pressure drop used by the manufacturer when the fan was rated? If not, this needs to be added to your total external pressure drop to accurately interpret fan airflow.

Best Solution: Record Pressures at Start-up

As you can see, it often takes some patient research to locate and interpret this information in the field and from published manufacturer specifications.

One solution is to measure and record pressures on the equipment during system commissioning at start-up.

When the system is commissioned, the equipment is either new or in like-new conditions. The fan and system airflows have been verified, as well as other relevant associated tests. System performance is ripe to harvest reliable and credible pressure data. This information can then be used as a benchmark to compare future pressure tests against.

By comparing subsequent pressure tests to those measured during commissioning, you can track system deterioration over time. A savvy technician can then pinpoint and correct system defects more easily to keep the system performing well throughout its life.

The next time static pressure testing has you stumped, or you feel the need to improve the level of your diagnostics, apply these principles. As you practice these skills, you’ll be led by your new knowledge to test and diagnose system pressures with increasing accuracy and success.

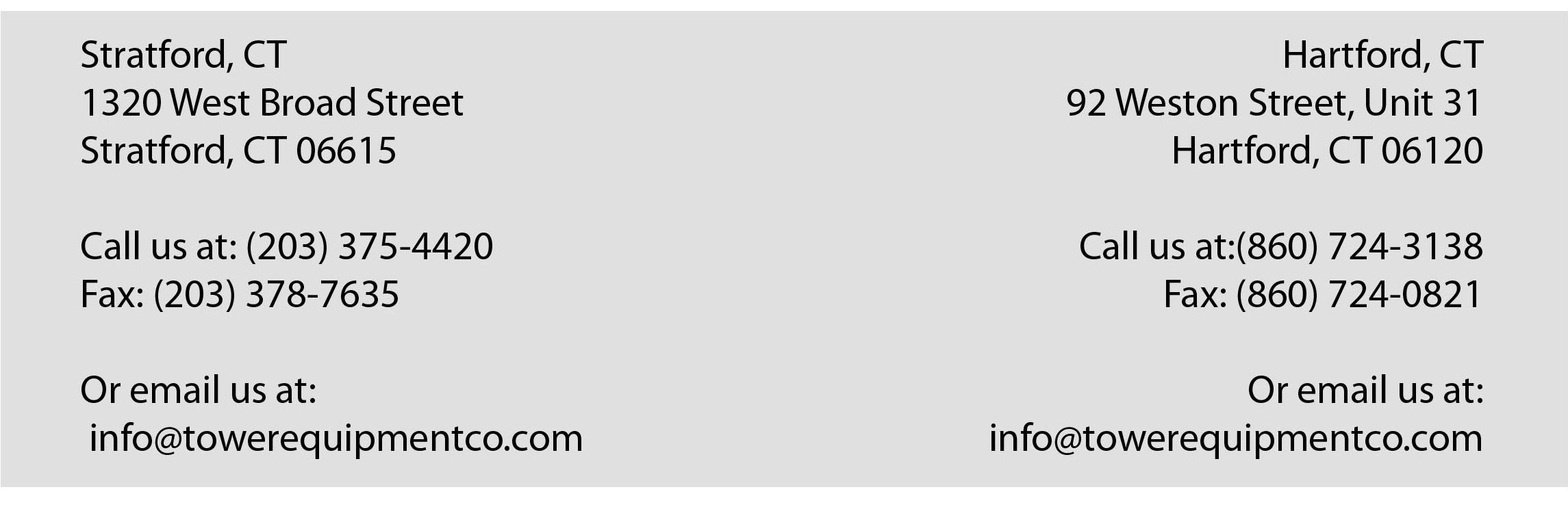

Have questions? Tower Equipments Professionals have the answers! Contact us today at:

Read the original article here

Read the original article here

0 Comments Leave a comment